Lots of people like doing international trade of bags on internet, part of them go smoothly, part of them will encounter quality problem, how we could ensure we could stop this problem before complete order? We must need do quality control inspection. But how we do the quality control inspection, lets check it step by step.

Step 1: Get Ready for Inspection

Confirm Sampling standard

Compared with other industries, the inspection standards of the bag industry are still relatively low. Generally, there are only two sampling standards: AQL4.0 and AQL6.5. Therefore, as long as the goods have no major functional defects, there should be no major problems with the inspection. The severity of poor quality is generally divided into three grades: severe, normal and minor. In a batch of products, as long as one product is seriously defective, the batch of products will be judged as unqualified, and the number of defective products with general and minor quality problems will be judged according to the

provisions of the AQL standard. Eligibility. The selection of the AQL sampling standard is decided after negotiation between the customer and the supplier, and is not unilaterally proposed. Which standard to use for AQL4.0 and AQL6.5 will be decided by the two parties after discussion. As a buyer in the bag industry, he can also control the standard according to the grade of bag, so as to ensure that the product quality is qualified. For example, high-end brands, high-end leather bags, etc., should be controlled by higher AQL4.0 or even AQL2.5, while low-end bags such as shopping bags, AQL6.5 should be sufficient. Knowing this criterion for eligibility and the relationship between bag grade and quality, we believe that the factory should know how to pass the customer’s inspection: as an buyer, you should also be able to judge whether It can be released without accidents.

Offered the inspector inspected reference

The sample is a bag made according to the bag or drawing provided by the customer for the customer to confirm. After the customer confirms OK, it is the so-called bag sample. The bag sample can be divided into development sample, structural sample, pre-production sample, QC sample, sales sample, production sample etc. according to its function. What we need offer inspector is the final sample you need the inspector to compare with the bulk and your final comment for this sample.

Color card refers to the color of the material that has been confirmed by the customer (or superior), and a few small pieces of material that include the characteristics of the material. The color card confirmed by the your side.

Confirmed the product complete status

Before start the Final quality inspection, need confirm that the finished product must be 100% sewn, and at least 80% packaged, otherwise we could not start the inspection.

Step 2: Quality Inspection

(1) Inspection Place

The inspection place must be spacious and bright, which could ensure you could examine products clearly. If that is not , inspector could require to change the inspection site.

(2) Select the box:

A Select samples strictly in accordance with AQL’s sampling standards:

B confirm all the products are ready

C Inspector must go to the warehouse to select the boxes by himself to prevent the factory from cheating. Inspectors must always be vigilant. When selecting the box, it must be randomly selected from the middle or bottom, and the drawing range must be wide;

D, Write down the selected box number, and make a mark on the carton to prevent the package from being changed by factory. Before opening the box at the inspection place, check the box number and mark for any abnormalities, if not start inspection:

(3) Inspection carton:

A. If the product needs to be held in a box, first perform a box drop test according to the customer’s box drop request to check whether the packaging is safe. Especially high-end handbags for long-distance transportation, if the damage caused by the poor quality of the carton is not worth the loss;

- Check that the carton is not damaged, whether it is a special foreign trade box (there is a special commodity inspection number)

(4) Inspection Outlook Of products:

A The inspector should make a form in the preparation before the inspection, and record the key inspection contents. The content of these records is naturally the focus of the inspection: B Check whether the material and color of the main materials, auxiliary materials, and lining are according to the sample and color card according to the model.

C Check whether the material, processing technology and shape of hardware, zippers and other accessories are according to the sample:

D Whether the bag size meets the requirements:

The general error range is plus or minus 2MM. The special structure requirements can only be greater than or equal to the design size, and must not be less than the design size, such as the size of the main bag of the computer or the computer bag:

E Check whether the appearance of the bag is symmetrical, plump and beautiful:

F check whether there is a basis for the items that the customer has special requirements. If the material is required to be low-toxic, it is necessary to check whether the certification information provided by the factory is correct and effective.

G check whether there is a miss checking part. For example, there is an inner sling bag on the bag board, but it is forgotten to make it in the bulk goods.

If one of the above content is unqualified, the batch of goods shall be judged as unqualified and rejected.

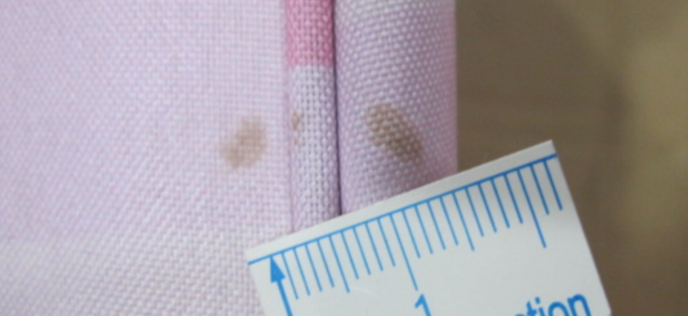

- Inspection Main Material:

A The cross-crotch defect is caused by uneven yarn tension or yarn fibers with different dye affinity. It appears as an uneven and unwanted dyed pattern on the fabric.

B Stained yarn and floating yarn:

Stained yarn means that the yarn count in the fabric is dirty,

Floating yarn refers to fabric floating on the surface of the fabric.

C Holes, scratches:

D Pattern is incorrect:

It is the incorrect weaving method of the batch fabric during the weaving process.

E Texture distortion:

F Texture unclear:

G Fabric defect:

A few defects appear in the spinning process of batch fabric yarn. Such as nodes, uneven thickness, yarn breakage, etc.

H The yarn knot is bad;

In the process of weaving, sometimes the warp or weft will break, and we need to connect it to the weaver. The point of connection is called a knot. The wrong method of knotting can easily cause bad knots.

The weight, hand feel, and fiber type of the fabric do not meet the specified requirements:

The thickness of the yarn and the density of the yarn directly affect the weight of the fabric per unit area. Therefore, the weight of the fabric is an important parameter for judging the quality of the fabric.

Hand feel refers to the softness and smoothness of the fabric. It cannot be represented by a specific number. It can only be judged based on the feel of the material on the bag sample or color card to judge the feel of the fabric on the bag.

J Fleece is too long: The exposed part of the pile fabric is too long.

K The fleece part of the fabric is inconsistent:

If the design requirements are not met, the flocking part is uncoordinated and it is not good looking.

L Fabric pilling or fibers are easy to fall off:

The fibers in the raised part have poor cohesion between the fibers, and the fibers themselves are easy to fall off.

M yarn breakage, roving;

Yarn break refers to the lack of a piece of yarn in the middle of the fabric; Roving means that one or several yarns in the middle of the fabric are particularly thick.

N Discoloration of fabric:

Discoloration inspection of fabric: Put a small piece of material into half a cup of boiling water at about 80 degrees to see the change of water color.

- Color And Silk Screen

A color is too old or too fresh, not correct:

B staining defect:

Silk screen error;The screen printing is not performed according to the size, position or color of the pattern requested by the customer, or the color of the screen printing is quite different.

C Silk screen defects:

Such as the outline of the silk screen is not clear or there are jagged, double images, flying oil, leaking points, through the bottom, shifting, fading, silk screen oil adhesion, etc.

D For the discoloration inspection of the silk screen, 3MM transparent glue can be rubbed back and forth on the surface of the silk screen to see if it fades.

E Color difference of fabric;

Because the color is difficult to control, there will always be chromatic aberrations in the colors printed and dyed in printing and dyeing factories. If it is too large, it can be judged as two colors. Therefore, an acceptable range of angular beauty must be determined. Generally, it can be coded within 90% of the color of the pallet

F Color difference between cutting pieces:

If the pattern of the piece is reversed, it will also cause chromatic aberration in different parts of the same handbag. The reason is caused by the refraction of light.

G other.

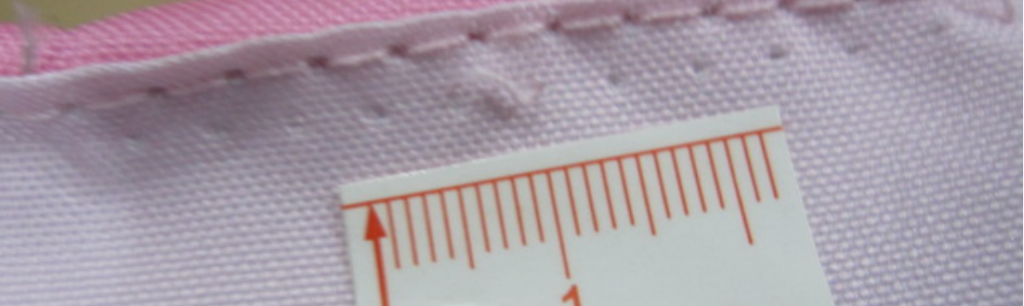

- Structure:

A Check the stressed parts:

The main inspection parts are: handles, shoulder strap ears, whether there are knock-down needles in all exposed sewing parts, whether the joints are easy to crack due to force, etc.:

B color asymmetry:

There is a color difference between the material and the material. Therefore, when cutting pieces on the cutting bed, the color difference should be selected according to the good color difference, and the cutting should be matched. For example, the bag cover and the front panel are designed to be the same color material. However, due to the color difference between the materials, the upper flap and the front panel of the bag will appear the color is quite different and not beautiful.

C The wrinkle of folding distribution is inconsistent:

The wrinkle of folding is to overlap a certain part of a certain piece to form a big end and a small shape. Its shape is like the folding fan we usually see, which should be easier to understand. Inconsistent distribution will cause a few big folds, a few small folds, which is not beautiful.

D The texture of the fabric is misplaced:

For example, in striped jacquard fabric, when two pieces of cut are stitched together, when the two ends of the stripe are not aligned, it is called texture misalignment, and the garment is called the right grid. It will definitely not look good.

E Folding (also called piping, bags are called binding) is not neat;

After the fabric is cut, the fibers at the edge are easy to fall off and are not beautiful, so it needs to be wrapped inside. There are two methods. One method is to sew the edge part of the fabric through a double loop (folded in half and then fold in half) or sewn with piping material. And the other is to wrap them with edging material and sew them.

F folding distortion:

G Folding irregularly:

H stripe asymmetry:

For example, for the rectangular jacquard material used in the left and right loans, the length and width of the left and right pockets are just reversed, forming a left-right asymmetry.

I Broken needle:

J Missing stitching or not finished;

K Wrong stitch;

L Sew waste into the product by mistake:

M The shape of the opening is skewed, twisted or curved ;

N The opening is not smooth, Bad connection uneven or irregular edge seams:Edge seam refers to the junction of two pieces of material.

O side seams are wavy, wrinkled, wrinkled or twisted:

P burst:

Q The side seams are not straight when the side seams cross:

R disconnection:

S Missing the needle, the line is not firm or the needle is not knocked down:

Two or three stitches need to be stitched back and forth at the first and half inch of the stitching line, which is called knock-down stitch. The purpose is to prevent the stitches from loosening from the beginning or the end.

T surface line offset;

U Irregularly routed

V Line is too loose, too tight or sometimes loose and sometimes tight

W other.

- Accessories and ingredients

A button is damaged, missing, not strong, and the buttons are not straight:

B buttonhole rings, buckles, rivets, zippers, and other accessories are damaged, missing, inflexible or even unusable, etc.:

C The back of the quilting stitching is not clean

When engraving (embroidery), a layer of sticky cloth needs to be glued behind the material, and this layer of sticky fabric should be removed after the engraving is completed. What I mean here is that this layer of sticky fabric has not been removed cleanly.Including floating lines, broken lines, few lines, wrong color lines, unclear outlines, etc.:

D webbing, decorative tape, edging tape, Velcro and other ingredients are poor, inappropriate, weak or missing:

E Backing is melting, missing or exposure:

In order to form the general bags, to increase the hardness, a layer of other auxiliary materials (also called supporting materials and linings) are often glued behind the main structural material. The commonly used linings are miscellaneous rubber and non-woven fabrics , which is composed of molecular chemicals and is easy to melt at high temperatures. If the backing is melted or omitted, it will naturally not be able to increase the hardness as it should. Exposed the backing affects the appearance.

F other.

- Bag inspection

A Whether the bag is as the same as the referenced sample, pay special attention to symmetry:

B Strictly check whether the revised content is corrected: whether there are missing parts (such as one less pouch, one less hardware accessories, etc.): whether the colors between the materials are coordinated, etc.:

C The bag shape is severely distorted and the bag is wrinkled:

D ironing stains:

E Obvious indentation;

F If the stitches do not match:

stitches do not match the color of the material, sewing needles, tacks, pins, etc. have not been removed:

G The template traces are visible:

H thread is not cut clean:

I other.

(10), size inspection

A size exceeds the allowable range:Unbalanced bag’s center of gravity:

(11), packaging and internal label

A Carton label and carton sticker are incorrect:

Check the carton label according to the packaging information. The contents of the carton mark often include the customer’s P.0. number, article number, color, gross weight, net weight, place of origin, and carton number. It is necessary to compare word by word, and check each item. Don’t make mistakes.

There is the information of the commodity on the carton sticker, and the customs may check the customs declaration data accordingly. Once the discrepancy is found, the customs will detains the goods, and don’t think about leaving for the time being. Maybe the customs thinks you are smuggling drugs or something.

There are two types of box labels usually: front label and side label. The front mark refers to the mark printed on the front of the carton, and the side mark refers to the mark printed on the side of the carton. The content of the positive label includes: The content of the side label includes:

B Carton quality and packing method

Check whether the carton is nailed or not nailed according to the packaging information (Europeans like nails and Americans like nailless ones). Whether there is a packing belt, if so, whether it is manual or mechanical (Europeans like mechanical packing, Americans like manual packing). Finally, see if the customers have requirements for the sealing tape (yellow tape, transparent tape or kraft tape, etc.), do they require I-shaped sealing, etc. Sometimes the customer will request the use of special sealing tape, you must check whether the sealing tape is consistent with the information provided by the guest.

C. The size of the carton does not meet the requirements: Focus on checking whether the carton is deformed or cracked after loading the goods. If the size is too small,

It is very difficult to carry during transportation, the goods are easily damaged, so the factory must be required to reorder the cartons. If the size is too large, the cartons will collapse due to gravity during stacking, so the cartons can only be reordered and reloaded. The size of the carton has been changed. Don’t forget to change the customs declaration and packing information, because the change in the size of the carton will definitely affect the quantity of a container and the total weight of the container. If the size is only larger, you can ask the factory to stuff paper in the carton or increase the ceiling and the number for filling: at this time, there is no need to change other information.

D Bags is not folded and stacked correctly:

Many companies will require the factory to take pictures of the handbag folding method for confirmation. Its purpose is to ensure that the handbag is minimized and shaped well during transportation and storage. The next step is to save space as much as possible and reduce transportation costs.

E Wrong Cartons:Put what should have been in bag A into bag B.

F The packing quantity is incorrect and check whether there is a cover:

Some customers require that the top and bottom of the carton should be placed on the top and bottom of the carton to check for any omissions.

G Size, color, content of the tag, , price tags, and UPC stickers is right or not.

There will be a customer’s LOGO on the listing, and the price of a product has a great relationship with the brand effect of the LOGO. Therefore, we must strictly check whether the LOGO on the listing is clear and beautiful: If there are more listings, pay attention to each listing. s position. If several listings are hung in one place, pay attention to the order before and after listings. There are barcodes containing product information on price tags and UPC stickers. You must strictly check the barcode numbers and whether they can be scanned quickly and without errors.

H Wrong stitching or wrong position, omission, damage, etc. of internal label, woven label, etc.:

The inner label includes the ingredient label, the washing water label, the place of origin, etc. As the name implies, the inner label must be carried in the bag, and a handbag may require several different types of inner labels. The woven label belongs to the outer label, and the outer label should be mounted on the surface of the bag

If there are many internal labels, please check the position of each internal label, and don’t make mistakes.

I Check the material, size, opening direction and closing requirements of the plastic bag;

Check the material, size, opening direction and closing of the plastic bag carefully according to the packaging information. Different materials will have a great influence on the molding and storage of the handbag and the silk screen: whether the size is appropriate or not, if the size is too small, it will inevitably deform the handbag, so the factory must be required to replace the plastic bag; the incorrect opening direction will also cause the handbag to not fit into the bag.

J The contents of the plastic bag are wrong:

If the warning notes is on the plastic bag, and the logo, how about the sticker need be applied onto plastic bag,

Step 4 write the inspecting report

When the whole inspection is completed, the inspector will offer the report, we could have the final quality result.

Conclusion

This article is for your reference how to examine bags quality for your bulk order, just for your reference. There may be any missing place, we will keep update timely.